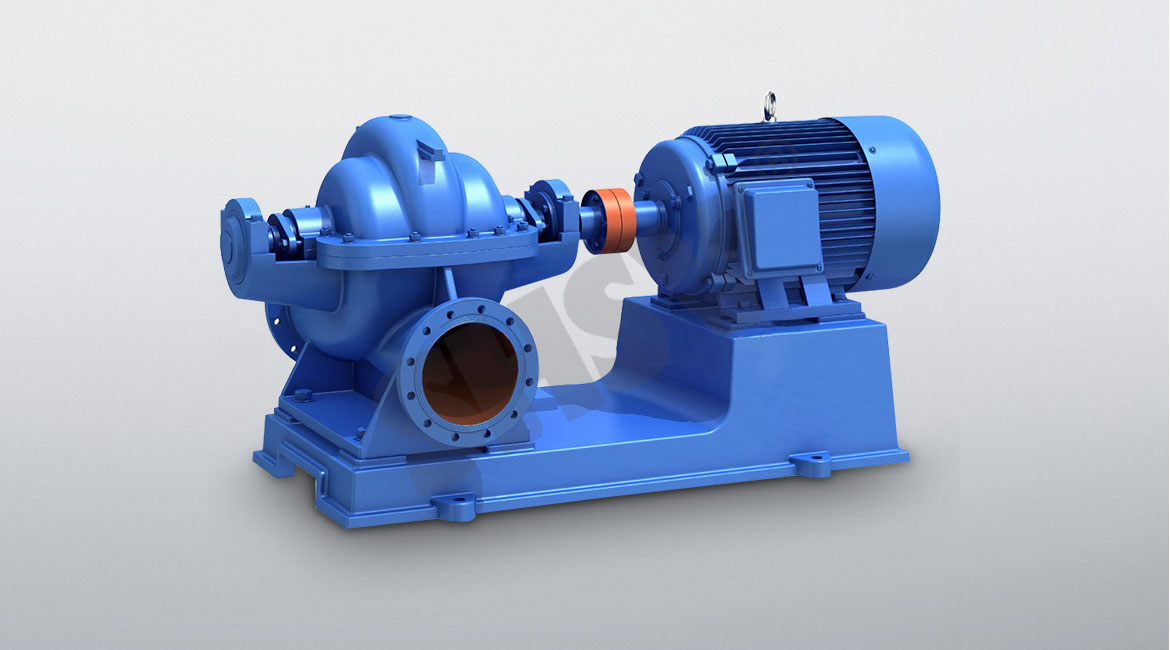

Overview of single stage double suction middle opening pump

S type pump is the replacement of Sh type single stage double suction, horizontal middle open centrifugal pump, for the transport of clean water and physical and chemical properties similar to water liquid (liquid high temperature does not exceed 80℃).Suitable for water supply and drainage of factories, mines, cities and power stations, irrigation and drainage of farmland and various water conservancy projects.SM, SF and SY pumps are formed on the basis of s-type pumps by changing the material, sealing, structure and other measures, which are respectively suitable for conveying mud and sand water quality or wear-resisting requirements, corrosion resistance requirements or oil and other media.

Single stage double suction middle opening pump model significance

150S78A

150—Pump inlet diameter is150mm

S - horizontal single stage double suction pump

SM - single stage double suction wear-resisting pump

SF - single stage double suction corrosion resistant pump

SY - single stage double suction pump

78 -- design point head is 78m

A - cutting impeller diameter, Ⅰ said impeller diameter increased

6Sh—6A

6 -- pump inlet diameter 6 "(150mm)

Sh - horizontal single stage double suction pump

6 -- round 1/10 of the specific speed of the pump

A - external diameter cutting code of impeller

Single stage double suction middle opening pump performance range

Flow rate: 160 ~ 18000m3/s

Head: 12 ~ 125m

Single - stage double - suction middle - opening pump structure characteristics

1. The inlet and outlet of the S, SM, SF and SY pumps are all below the pump axis and perpendicular to the axis in a horizontal direction. The pump shell is opened.From the direction of the drive end to the pump, the pump rotates clockwise, or counterclockwise according to the need.

2, S, SM, SF, SY pump main parts: pump body, pump cover, impeller, shaft, double suction seal ring, shaft sleeve, bearing, etc.

3. After static balance check, the impeller is fixed by the shaft sleeve and the shaft sleeve nuts on both sides, and its axial position can be adjusted by the shaft sleeve nuts.The axial force of impeller is balanced by the symmetrical arrangement of blades, while the residual axial force is borne by the shaft end bearing.

4. The pump shaft is supported by two single row radial ball bearings or four radial thrust ball bearings, which are installed in the bearing body at both ends of the pump body and lubricated with butter or thin oil.

5. The water pump is directly driven by an electric motor through an elastic sleeve pin coupling.

6. The shaft seal is a soft packing seal. In order to cool and lubricate the sealing cavity and prevent air from entering the pump, a packing ring is installed between the packing rings.

Single stage double suction center opening pump material

|

Part name

|

Pump type

|

Pump type

|

Pump type

|

Pump type

|

|

S

|

SM

|

SY

|

SF

|

|

Pump body

|

HT200

|

QT500-7

|

HT200或ZG230-450

|

ZG1Cr13 or ZG1Cr18Ni9Ti

|

|

Pump cover

|

HT200

|

QT500-7

|

HT200或ZG230-450

|

ZG1Cr13 or ZG1Cr18Ni9Ti

|

|

Impeller

|

HT200

|

KmTbCr15Mo3

|

ZG230-450

|

ZG1Cr13 or ZG1Cr18Ni9Ti

|

|

Shaft

|

45

|

45

|

45

|

2Cr13

|

|

Shaft sleeve

|

HT200

|

QT500-7

|

HT200

|

ZG1Cr13 or ZG1Cr18Ni9Ti

|

|

Sealing ring

|

HT200

|

KmTbCr15Mo3

|

HT200

|

ZG1Cr13 or ZG1Cr18Ni9Ti

|

Single stage double suction middle opening pump structure drawing

1. The suction inlet and discharge outlet of this type of pump are all below the pump axis, and the horizontal direction is in a vertical position with the axis and the pump shell.According to the special order needs of the user, it can also be changed to "clockwise" needle rotation.

2, the main other parts of this pump: pump body, pump cover, impeller, shaft, double suction sealing ring, shaft sleeve, bearing, etc.In addition to the shaft material for quality carbon steel, the rest of the cast iron made.

3, pump body and pump cover constitute the impeller studio, in the inlet and outlet water flange is made with the installation of vacuum gauge and pressure gauge pipe screw hole, the lower part of the inlet and outlet water flange is made with the drainage pipe screw hole.

4. The impeller is fixed by the shaft sleeve and the shaft sleeve nuts on both sides after the static balance check, and its axial position can be adjusted by the shaft sleeve nuts. The axial force of the impeller is balanced by the symmetrical arrangement of the blades, and there may be some remaining axial forces which are borne by the bearing on the coaxial end.

5. The pump shaft is supported by two single row radial ball bearings, which are installed in the bearing body at both ends of the pump body. The bearings are lubricated with butter, and the double suction sealing ring is used to reduce the water leakage back to the suction chamber of the water pump.

6. The water pump is driven directly by the motor through the coupling.

7. The shaft seal is a soft packing seal. In order to cool and lubricate the sealing cavity and prevent air leakage into the pump, there is a water sealing ring between the packing.

|

No

|

Name

|

No

|

Name

|

|

1

|

Pump body

|

12

|

Bushing nut (right)

|

|

2

|

Pump cover

|

13

|

Bearing body

|

|

3

|

Pump shaft

|

14

|

Retaining bolt

|

|

4

|

Impeller

|

15

|

Bearing gland

|

|

5

|

Double suction seal ring

|

16

|

Coupling parts

|

|

6

|

Shaft sleeve

|

17

|

Round nut

|

|

7

|

Packing set

|

18

|

Bearing cover (a)

|

|

8

|

Dip pipe

|

19

|

Bushing nut (left)

|

|

9

|

Packing

|

20

|

Bearing retainer

|

|

10

|

Packing ring

|

21

|

Bearing cover (b)

|

|

11

|

Packing gland

|

22

|

End cover

|

Performance parameters of single stage double suction middle opening pump

|

Type

|

Q

(m3/h)

|

H

(m)

|

n

(r/min)

|

P(kw)

|

n

(%)

|

(NPSH)r(m)

|

|

Shaft

|

Motor

|

|

100S90

|

80

|

90

|

2950

|

30.1

|

37

|

65

|

2.5

|

|

100S90A

|

72

|

75

|

2950

|

23

|

30

|

64

|

2.5

|

|

150S100

|

160

|

100

|

2950

|

59.8

|

75

|

73

|

3.5

|

|

150S78

|

160

|

78

|

2950

|

45

|

55

|

75.5

|

3.7

|

|

150S78A

|

144

|

62

|

2950

|

33.4

|

45

|

72.6

|

3.7

|

|

150S50

|

160

|

50

|

2950

|

27.3

|

37

|

80.4

|

3.9

|

|

150S50A

|

144

|

40

|

2950

|

20.0

|

30

|

75.5

|

3.9

|

|

150S50B

|

133

|

36

|

2950

|

18.0

|

22

|

72.5

|

3.9

|

|

200S95

|

280

|

95

|

2950

|

91.4

|

132

|

79.2

|

5.3

|

|

200S95A

|

270

|

85

|

2950

|

83.3

|

110

|

75

|

5.3

|

|

200S95B

|

260

|

75

|

2950

|

73.8

|

90

|

72

|

5.3

|

|

200S63

|

280

|

63

|

2950

|

58.3

|

75

|

82.7

|

5.8

|

|

200S63A

|

270

|

46

|

2950

|

45.1

|

55

|

75

|

5.8

|

|

200S42

|

280

|

42

|

2950

|

38.1

|

45

|

84.2

|

6

|

|

200S42A

|

270

|

36

|

2950

|

33.1

|

37

|

80

|

6

|

|

250S65

|

485

|

65

|

1450

|

109.2

|

132

|

78.6

|

3.1

|

|

250S65A

|

420

|

48

|

1450

|

88.5

|

90

|

77.7

|

3.1

|

|

250S39

|

485

|

39

|

1450

|

61.5

|

75

|

83.6

|

3.2

|

|

250S39A

|

468

|

30

|

1450

|

48.4

|

55

|

79

|

3.2

|

|

250S24

|

485

|

24

|

1450

|

36.9

|

45

|

85.8

|

3.5

|

|

250S24A

|

414

|

20

|

1450

|

27.2

|

37

|

83.3

|

3.5

|

|

250S14

|

485

|

14

|

1450

|

21.5

|

30

|

85.8

|

3.8

|

|

250S14A

|

432

|

11

|

1450

|

15.2

|

18.5

|

82.7

|

3.8

|

|

300S90

|

790

|

90

|

1450

|

243

|

320

|

79.6

|

4.2

|

|

300S90A

|

756

|

78

|

1450

|

216.4

|

280

|

74.2

|

4.2

|

|

300S90B

|

720

|

67

|

1450

|

180

|

220

|

73

|

4.2

|

|

300S58

|

790

|

58

|

1450

|

147.9

|

200

|

84.2

|

4.4

|

|

300S58A

|

720

|

49

|

1450

|

118.0

|

160

|

82.5

|

4.4

|

|

300S58B

|

684

|

43

|

1450

|

100

|

132

|

80

|

4.4

|

|

300S32

|

790

|

32

|

1450

|

79

|

90

|

86.8

|

4.6

|

|

300S32A

|

720

|

26

|

1450

|

60.7

|

75

|

84

|

4.6

|

|

300S19

|

790

|

19

|

1450

|

47.1

|

55

|

86.8

|

5.2

|

|

300S19A

|

720

|

16

|

1450

|

39.2

|

45

|

80

|

5.2

|

|

300S12

|

790

|

12

|

1450

|

30.4

|

37

|

84.8

|

5.5

|

|

300S12A

|

684

|

10

|

1450

|

23.9

|

30

|

78.4

|

5.5

|

|

350S125

|

1260

|

125

|

1450

|

533

|

680

|

80.5

|

5.4

|

|

350S125A

|

1181

|

112

|

1450

|

461

|

570

|

78.2

|

5.4

|

|

350S125B

|

1098

|

96

|

1450

|

373

|

500

|

77

|

5.4

|

|

350S75

|

1260

|

75

|

1450

|

303

|

360

|

85.2

|

5.8

|

|

350S75A

|

1170

|

65

|

1450

|

244.4

|

280

|

84.2

|

5.8

|

|

350S75B

|

1080

|

55

|

1450

|

196.3

|

220

|

82.4

|

5.8

|

|

350S44

|

1260

|

44

|

1450

|

172.5

|

220

|

87.5

|

6.3

|

|

350S44A

|

1116

|

36

|

1450

|

129.5

|

160

|

84.5

|

6.3

|

|

350S26

|

1260

|

26

|

1450

|

102

|

132

|

87.5

|

6.7

|

|

350S26A

|

1116

|

21

|

1450

|

76.9

|

90

|

83.4

|

6.7

|

|

350S16

|

1260

|

16

|

1450

|

64.4

|

75

|

85.4

|

7.1

|

|

350S16A

|

1044

|

13

|

1450

|

47

|

55

|

78.3

|

7.1

|

|

400S90

|

1620

|

90

|

1450

|

473

|

560

|

84

|

6.2

|

|

400S90A

|

1460

|

73

|

1450

|

345

|

450

|

84

|

6.2

|

|

400S90B

|

1300

|

58

|

1450

|

245

|

315

|

84

|

6.2

|

|

400S40

|

1080

|

40

|

970

|

140

|

185

|

85

|

5.1

|

|

400S40A

|

1007

|

33

|

970

|

107

|

160

|

84.5

|

5.1

|

|

400S40B

|

870

|

26

|

970

|

73.3

|

110

|

84

|

5.1

|

|

500S98

|

2020

|

98

|

970

|

678.1

|

800

|

79.5

|

4.1

|

|

500S98A

|

1872

|

83

|

970

|

539

|

630

|

78.5

|

4.1

|

|

500S98B

|

1746

|

74

|

970

|

450.1

|

560

|

78.7

|

4.1

|

|

500S59

|

2020

|

59

|

970

|

388.2

|

450

|

83.6

|

4.5

|

|

500S59A

|

1872

|

49

|

970

|

332.32

|

400

|

75.6

|

4.5

|

|

500S59B

|

1746

|

40

|

970

|

255.8

|

315

|

74

|

4.5

|

|

500S35

|

2020

|

35

|

970

|

218.2

|

280

|

83.6

|

4.8

|

|

500S35A

|

1746

|

27

|

970

|

150.6

|

220

|

75.6

|

4.8

|

|

500S22

|

2020

|

22

|

970

|

143.6

|

185

|

74

|

5.2

|

|

500S22A

|

1746

|

17

|

970

|

100.6

|

132

|

88.2

|

5.2

|

|

500S13

|

2020

|

13

|

970

|

85.7

|

110

|

85.2

|

5.7

|

|

600S22

|

3170

|

22

|

970

|

215.8

|

250

|

84.2

|

7

|

|

600S22A

|

2860

|

18

|

970

|

161.1

|

185

|

80.3

|

7

|

|

600S32

|

3170

|

32

|

970

|

310.4

|

355

|

83.4

|

7

|

|

600S32A

|

2850

|

26

|

970

|

229

|

280

|

88

|

7

|

|

600S47

|

3170

|

47

|

970

|

456

|

560

|

87

|

6.5

|

|

600S47A

|

2920

|

40

|

970

|

361

|

450

|

89

|

6.5

|

|

600S75

|

3170

|

75

|

970

|

736

|

900

|

88

|

6

|

|

600S75A

|

2920

|

65

|

970

|

600.2

|

710

|

89

|

6

|

|

600S75B

|

3170

|

55

|

970

|

477.5

|

560

|

88

|

6

|

|

600S100

|

2950

|

100

|

970

|

1015.6

|

1250

|

87

|

6

|

|

600S100A

|

2710

|

90

|

970

|

875.4

|

1120

|

85

|

6

|

|

600S100B

|

3170

|

80

|

970

|

751.9

|

900

|

85

|

6

|

|

800S22

|

3000

|

22

|

730

|

370.2

|

450

|

84

|

7

|

|

800S22

|

2830

|

14

|

585

|

190.6

|

250

|

82

|

5

|

|

800S22A

|

5500

|

17

|

730

|

254.1

|

315

|

89

|

7

|

|

800S22A

|

4400

|

11

|

585

|

133.3

|

185

|

88

|

5

|

|

800S32

|

4830

|

32

|

730

|

538.5

|

630

|

87

|

74.5

|

|

800S32

|

3870

|

20

|

585

|

272.3

|

315

|

89

|

7

|

|

800S32A

|

5500

|

26

|

730

|

389

|

450

|

88

|

4.5

|

|

800S32A

|

3960

|

17

|

585

|

210.7

|

250

|

88

|

6.5

|

|

800S47

|

5500

|

47

|

730

|

782.2

|

1000

|

87

|

4.2

|

|

800S47

|

4400

|

30

|

585

|

403.9

|

450

|

90

|

6.5

|

|

800S47A

|

5070

|

40

|

730

|

621

|

710

|

89

|

4.2

|

|

800S47A

|

4060

|

25

|

585

|

314.1

|

355

|

89

|

6

|

|

800S76

|

5500

|

76

|

730

|

1293.6

|

1600

|

88

|

4.2

|

|

800S76

|

4400

|

49

|

585

|

674.9

|

800

|

88

|

6

|

|

800S76A

|

5080

|

65

|

730

|

1034

|

1250

|

87

|

6

|

|

800S76A

|

4070

|

42

|

585

|

541

|

630

|

86

|

4.2

|

|

800S76B

|

4680

|

55

|

730

|

824.7

|

1000

|

85

|

6

|

|

800S76B

|

3750

|

35

|

585

|

425.5

|

500

|

84

|

4

|