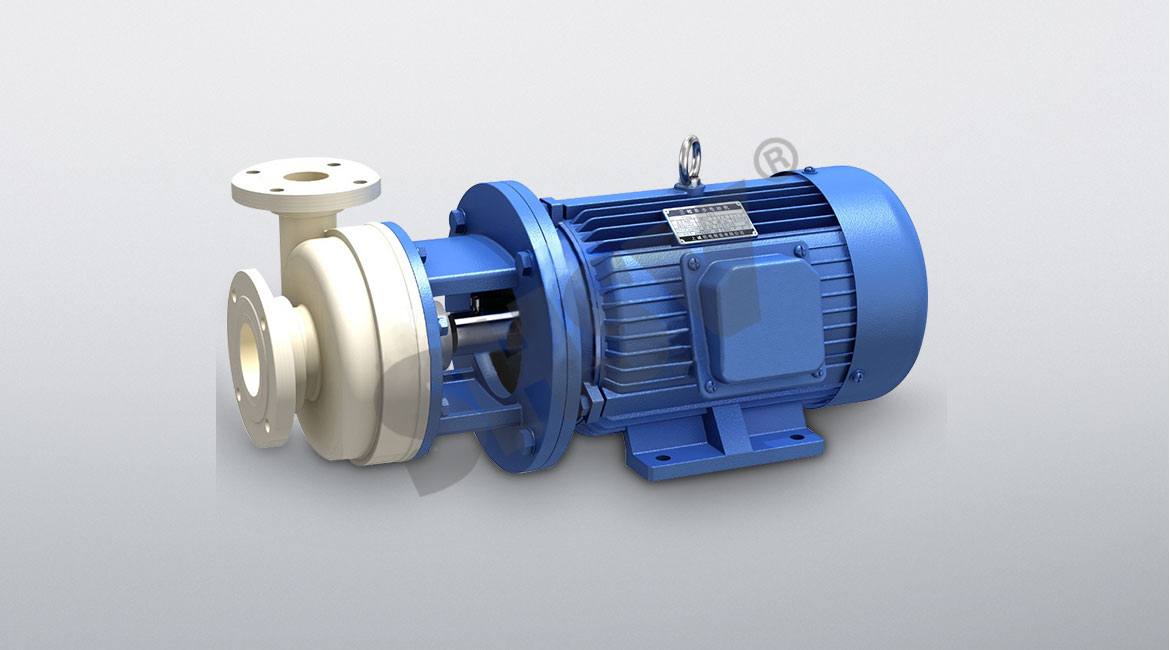

Product overview:

The corrosion resistant centrifugal pump is directly connected with the motor through the connecting shaft. The rotation direction of the corrosion resistant centrifugal pump is clockwise from the self-priming inlet to the motor, and the spout is perpendicular to the axis.Strong corrosion resistant centrifugal pump seal, choose ptfe (F4) bellows, corrosion resistant mechanical seal.PF corrosion resistant chemical pump is a horizontal centrifugal pump, but also a new energy-saving corrosion resistant chemical pump series products.

Corrosion resistant centrifugal pump according to the corrosion of the transmission medium and temperature conditions, the pump contact material can be divided into:

Reinforced polypropylene (denoted by the symbol PR) suitable temperature: -5-80℃.

(PVDF) polyvinylidene fluoride (symbol PF) applicable temperature -30-110℃.

Usually in the explosion-proof area, need to be equipped with explosion-proof motor.

Scope of use:

Corrosion resistant centrifugal pump can transport various concentrations of sulfuric acid, hydrochloric acid, acetic acid, phosphoric acid, chromic acid, oxalic acid, hydrofluoric acid and alkali, organic solvent, oxidant and other media under the temperature of -50℃ ~ 130℃.

Features:

1. Corrosion resistant pump mechanical seal is suitable for clean, non-suspended medium use.

2. Before the mechanical seal assembly of corrosion-resistant pumps, the pump body, impeller and seal cavity shall be cleaned, and the end faces of moving rings and static rings shall be strictly checked, and no minor scratches shall be allowed.

Wipe with a clean cloth and apply a clean oil.

3. Correct adjustment of spring compression, should not be too tight or too loose, so that it has a certain compression force, and can be light and flexible rotation.

4. Remove corrosion-resistant pump mechanical seal should be carefully, strictly prevent impact damage to the stationary and rotating ring sealing surface.

Performance parameters:

|

PF

|

Import diameter(mm)

|

Exit diameter(mm)

|

2900r/min

|

1450r/min

|

Uptake height

|

|

Traffic(m3/h)

|

lift(m)

|

%

|

KW

|

Traffic(m3/h)

|

lift(m)

|

%

|

KW

|

|

25-20-120

|

25

|

20

|

2.5

|

15

|

40

|

1.1

|

|

|

|

|

|

|

25-20-120

|

25

|

20

|

2

|

20

|

43

|

1.1

|

|

|

|

|

|

|

32-25-125

|

32

|

25

|

6.5

|

20

|

51

|

1.5

|

|

|

|

|

|

|

32-25-125

|

32

|

25

|

5

|

25

|

53

|

1.5

|

|

|

|

|

|

|

40-32-125

|

40

|

32

|

10

|

15

|

50

|

2.2

|

5

|

3.75

|

39

|

1.1

|

3

|

|

40-32-125

|

40

|

32

|

7.5

|

20

|

55

|

2.2

|

3.75

|

5

|

40

|

1.1

|

3

|

|

50-40-145

|

50

|

40

|

16

|

28

|

58

|

3

|

8

|

7

|

50

|

1.5

|

5

|

|

50-40-145

|

50

|

40

|

20

|

26

|

61

|

3

|

10

|

6.5

|

54

|

1.5

|

5

|

|

50-40-145

|

50

|

40

|

25

|

24

|

63

|

3

|

12.5

|

6

|

55

|

1.5

|

5

|

|

65-50-160

|

65

|

50

|

15

|

34

|

44

|

5.5

|

7.5

|

8.5

|

50

|

2.2

|

5

|

|

65-50-160

|

65

|

50

|

25

|

36

|

57

|

5.5

|

12.5

|

8

|

60

|

2.2

|

5

|

|

65-50-160

|

65

|

50

|

30

|

30

|

59

|

5.5

|

15

|

7.5

|

60

|

2.2

|

5

|

|

80-65-160

|

80

|

65

|

30

|

36

|

50

|

7.5

|

15

|

9

|

55

|

3

|

5

|

|

80-65-160

|

80

|

65

|

50

|

32

|

67

|

7.5

|

25

|

8

|

68

|

3

|

5

|

|

80-65-160

|

80

|

65

|

60

|

28

|

65

|

7.5

|

30

|

7.2

|

68

|

3

|

5

|

|

100-80-160

|

100

|

80

|

60

|

36

|

70

|

11

|

30

|

9.2

|

67

|

4

|

5

|

|

100-80-160

|

100

|

80

|

100

|

32

|

78

|

11

|

50

|

8

|

75

|

4

|

5

|

|

100-80-160

|

100

|

80

|

120

|

28

|

75

|

11

|

60

|

6.5

|

71

|

4

|

5

|